February 26, 1963 – October 7, 2004

I love you.

~ your sister, Melinda

February 26, 1963 – October 7, 2004

I love you.

~ your sister, Melinda

Yep, I’m still working on perfecting my merino spinning skills to develop enough confidence to start spinning for the Spin-Off sweater. I’ve split yard-long lengths of roving into thin strips, pre-draft these thin strips well and then spin with moderate twist. The singles are spun on a 9:1 ratio whorl and plied on a 7 1/2:1 ratio whorl.

I found that the long fibers of the tussah silk in this mixed merino/silk roving helped make it much easier to spin than a pure merino roving. Although I initially liked the mix of colors in pre-spun fiber once spun, I started finding that the red didn’t show up much in the singles. So after finishing a bobbin of singles I decided to ply the silk/merino singles with another bobbin of red merino singles to create a barber pole type yarn. The swatch in the top left corner was made from this barber pole yarn and the swatch below it was made from pure merino yarn.

While I haven’t been spending as much time online lately, I definitely find time to do something fiber related almost everyday. When I’m not knitting or spinning, I research patterns and try to think about design something simple. It all takes so much time so it doesn’t always translate into tangible results that I can post.

Washing hand knit wool clothing

Have you ever been tempted to throw your hand knit item in a front-loading washing machine? Last week I threw in my Merino Lace Socks (Interweave Knits, Summer 2003) and my first hand knit sweater made out of shrink resistant merino. It wasn’t the first time for the socks and I swear the sweater has been in before.

Well, the socks came out great but the sweater felted and shrank a bit. I should have known better. I’m not quite sure what I did differently that would cause the sweater felt. Perhaps I forgot to use the delicate cycle.

Luckily, this mistake wasn’t a total disaster. I can still wear the sweater but the fabric is no longer soft and springy. I’ve learned my lesson, from now on I’m hand washing all my hand knit items except socks make out of Koigu. Don’t you just love Koigu? These socks still look great even after a year mild wear and tear.

Irish Moss

I’ve managed to finish the front ribbing plus two rows on Irish Moss. After the first few rows I was able to get rid of the markers and do the rest by memory. If you look carefully you’ll see that the ribbing has several zigzag columns between 1/1 cross-stitch ribbing.

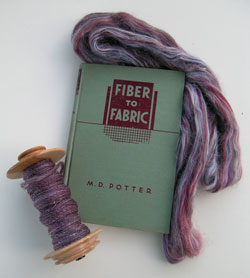

While browsing through books at a local used bookstore yesterday, I came upon interesting old business education textbook published in 1945. It describes the entire commercial process of manufacturing textiles from beginning to end and includes a detailed comparison of cotton, wool, linen, silk and rayon.

As I read through the first chapter called “Differential Qualities of Textile Fiber”, I began to understand why I enjoy working with rovings that include silk. My current spinning project (in the picture) is a roving with a combination of merino wool and tussah silk. Pure merino can be somewhat difficult to spin since the individual fibers can be quite short but when combined with long silk fibers, drafting the roving becomes much easier. This roving has a little too much white so I’m planning to ply it with a deep red pure merino single.

After learning more about the qualities of various fibers, I flipped to the third chapter called “Fiber to Yarn: Spinning”. In this chapter the author give an overview of each stage in spinning cotton and summarizes them as,

1. Lap to card sliver by the carding process.

2. Card sliver to comb sliver by the combing process (if the fiber is combed).

3. Sliver to roving by the drawing-out process.

4. Roving to yarn by the twisting process.

5. Reeled on bobbins, spools, or cones by the winding process.

So that clears up the difference between sliver and roving. If the book is correct, sliver is what is produced after combing/carding and drafting sliver produces roving.

In the 1940’s roving could be processed into fine yarn on a mule frame or ring frame. The book shows a picture of the mule frame, which I found quite fascinating. Here’s a picture from the library of congress that shows an early version of this machine (click on the photo for a closer view).

The picture in the book has a caption that says, “The mule spinning frame travels forward to draw out the roving, spinning it into yarn of a desired size. As the frame returns to its original position, the yarn is wound on bobbins.” In this picture it looks like the boys are fiddling with the spindles. Notice the wheels in the lower left corner. These wheels must help in moving the row of spindles to draw out the fiber and then wind it back on. Now if I only had one of these frames, I’m sure my production capabilities would sky rocket.

By the way, did you know that John Edwards has a bachelor’s degree in textile technology?

Even though I’ve been very distracted* this week I managed to cast on and work the first four rows of Irish Moss. As you can see I used plenty of markers to keep track of stitches.

Yes, that’s all that I’ve done in one week. Kind of pitiful, but the pattern is much more difficult then most and takes all my attention when I’m knitting it so I haven’t attempted to take it along on the bus. That’s why I haven’t gotten very far.

Here’s the project that I’ve been knitting while on the bus. I got this Pretty Comfy Sock pattern via Emma’s blog in May.

I tend to be a tight knitter and ended up using 3.5mm needles to get the correct gauge. Just like Emma, I’ll be using PGR’s short-row heels.

Back in the days when I had time to read the Socknitters list, I saved a post by Maggie Dicey that mentioned using coil-less safety pins (like the ones in the Irish Moss photo) to mark the working yarn instead of doing yarn-overs. Here are her exact words.

“The purpose of the YO is to make the turning thread from the previous row(s) available to be worked with the following stitch. You can achieve the same thing by hanging a coil-less safety pin or a length of waste thread over the working yarn close to the needle when you make the turn. Then when you get back to the turning point, lift up on the thread or pin and slide the loop(s) onto the left needle and proceed as above.” She then goes on to mention that this is known as Japanese short-rowing.

As some of you might remember, I took a Japanese short-rowing class recently and this is exactly what the teacher had us do. I asked her if she had tried it on socks and she hadn’t. I was curious because I remember reading in one of PGR’s books that that Japanese short-rows should only be used if there are a few stitches between each turn. I can’t remember why but I’m sure she tried it and would have mentioned it in her sock book if it could be done.

So I bring this short-row thing up because I’m going to try a new twist on this technique by using the coil-less safety pins to hold the yarn-overs in an effort to keep the stitches very tight. I’m about to start the heels so we will soon see how it works.

*I’ve been thinking of what to do with the purple wool & silk fiber that I spun a few weeks ago. I’ve been looking for the perfect pattern but might just attempt to design a hat or a mobious scarf.

This weekend I set aside my knitting to look for bears with a North Cascades Institute class taught by Chris Morgan. Although we saw many bear signs we didn’t actually see one. If you’re ever interested in learning more about bears, Chris gives a very informative and highly entertaining class.

Being such an avid knitter I always keep an eye out for any interesting sweaters that catch my eye wherever I go. This afternoon on my way to the bus, I spied a woman wearing a very interesting multi-colored hand knit sweater. At least I think it was hand knit.

As I stood behind her waiting for the street light to change, I noticed that my eyes started seeing very subtle large diamond shapes in the fabric, with some of the diamonds being more prominent then others. Perhaps the diamonds blended together so well because each appeared to be knitted with two strands of yarn. It sort of reminded me of color blended quilts that I’ve seen but with a much more subtle affect. It would be simply gorgeous done in hand spun yarns.

I did a google search for color blended sweater patterns but didn’t come up with anything. If anyone has heard of a pattern like this I’d be interested in learning more about it. In the mean time, I’ll keep searching the web.

Fiber: Rainbow Roving by Crosspatch Creations

Content: Wool, Tussah Silk, Silk Noil

Approximate weight: 4oz.

Preparation: Carded (?)

Source: Bellwether

Equipment: wheel

11:1 ratio whorl for singles

7-1/2 ratio whorl for plying

Method: semi-worsted, inch by inch short draw

Twist: 7 – 9 plied twists per inch

Wraps Per Inch: 12 – 14

Needles: 3.25mm

Tension/Gauge:

26 sts = 4-1/4 inches

Possible Project: Socks – if there’s enough

Notes: My best spinning results yet. I love this fiber. It’s soft but not whimpy. Most importantly, the knitted swatch is just as beautiful as the skein.

I decided to give Jamieson’s Soft Shetland one more try without the garter stitch boarder and didn’t measure the swatch until it was completely finished and washed. Voilà, the second swatch passes muster. I’ll start casting on the first piece when my work schedule calms down a bit.

I’ve been unwinding after long days at work by spinning the Rainbow Roving that I picked up at the Back Sheep Gathering this summer. Oh, this roving is so pleasant to spin in a relaxed fashion that I haven’t been too concerned about measure twists per inch.

I’ve gotten a couple of comments about my sock blockers and thought I would show what one looks like without the sock.

I’ve gotten a couple of comments about my sock blockers and thought I would show what one looks like without the sock.

Not too exciting except for the price, which was virtually nil. I’ve seen plastic and wooden blockers at the local knitting stores but thought the prices ($25 – $30) were too steep. The Knitting Zone has some photos of how to make them with plastic coated hangers.

Just as Mary from The Knitting Zone commented on her web site, blockers work great for drying and taking pictures otherwise there’s really no need to block socks.

Donna, the ball of yarn in the photo is what I had left after making the Crossing Cables socks for a size 7.5 US shoe. It’s probably not enough to make baby socks but big enough that I won’t donate it to my cat’s yarn ball collection.

The leg is about the same length as the foot, 9 inches from the tip of the heel. While the pattern calls for a 3mm needle for a woman’s sock and 3.5mm for the leg of a man’s sock, I used a size 2.5mm needle for the foot and 2.75mm for the leg. If I had it to do over again I would have use the 2.75mm needles for the whole sock. Just for reference, I tested my tension in stockenette while using the 2.75mm needles and found I was getting 7 stitches per inch. So, while I loved using Mountain Colors Bearfoot yarn, it might not be the right choice for this pattern unless you can make some adjustments or you don’t mind loose tension. I tried using 3mm needles but the tension was too loose for my tastes. Perhaps the MC’s Weaver’s Wool Quarters would work better, if you need larger socks.

I wanted to deliver the Crossing Cables socks to my mother this weekend so I spent most of Saturday and part of Sunday finishing the second sock. Of course, the socks were well received.

This is such an enjoyable pattern that I plan to make another pair for myself. I’ve been looking at various tweed yarns for the next pair and found some superwash red tweed called Smart by Sandnes while shopping at Sew EZ Too in Spokane this weekend. The price was right so I also picked up enough for some dark blue tweed socks.

You must be logged in to post a comment.